Recovery of vanadium from waste dumps

Background

Core has a partnership with South Africa technology company IPEX to further commercialise innovative hydrometallurgical technologies used for the recovery of metal values from low grade resources such as vanadium calcine tailings, to produce premium products with purities exceeding 99.5%.

Vanadium Redox Flow Batteries (VRFBs) are attracting a lot of attention because of their mass power storage ability, combined with their inherent simplicity of construction, use and safety. Core IPEX’s offers much improved processes to produce VRFB electrolyte.

The Core IPEX VRFB technology is proven at commercial scale at Wapadskloof, South Africa, on vanadium calcine tailings. It is currently operated under licence by ENVEX on the tailings of a major primary vanadium producer in Witbank, South Africa.

Project development timelines

The typical project development timelines are:

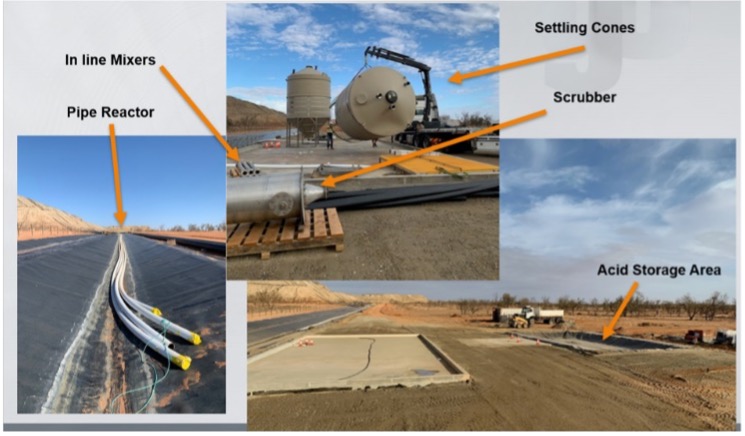

- Establishment and plant construction within 3 months

- Regular product delivery commences within 1 month of commissioning

- Steady state within three months of commissioning and operating profitably on a low-grade feed liquor concentration of less than 300 ppm V₂O₅

- Average plant availability above 98%.

Results

Core IPEX’s technology is currently producing vanadyl solutions at around 99.6% grade. Recent investigations showed that impurity levels may be further reduced by upgrading equipment used for cycle transition rinsing which is expected to achieve >99.9% purity levels.

Complete demineralisation of process water is currently being incorporated into the flow sheet to further reduce impurity traces by around 300ppm. This further enhancement promises vanadyl sulphate solution of close to ultra-pure “four nines” (≈99.99% grade).

Further pilot scale trials are planned in 2020 and beyond to showcase improved purity levels.

Conversion of vanadyl sulphate to VRFB electrolyte will be carried out in the Core IPEX piloting facilities in Brisbane.

This promises premium quality electrolyte at a compellingly low cost compared to conventional processing alternatives.