Know All About Core Resources' Plant Services

Operation of a pilot plant to a bankable standard is a difficult task, and at Core you can be guaranteed that all testing will be carried out in a timely and professional manner in advanced technical facilities. Core has over 30 years’ experience in the design and operation of pilot plants and is well versed in the sometimes-onerous requirements needed to achieve bankable status.

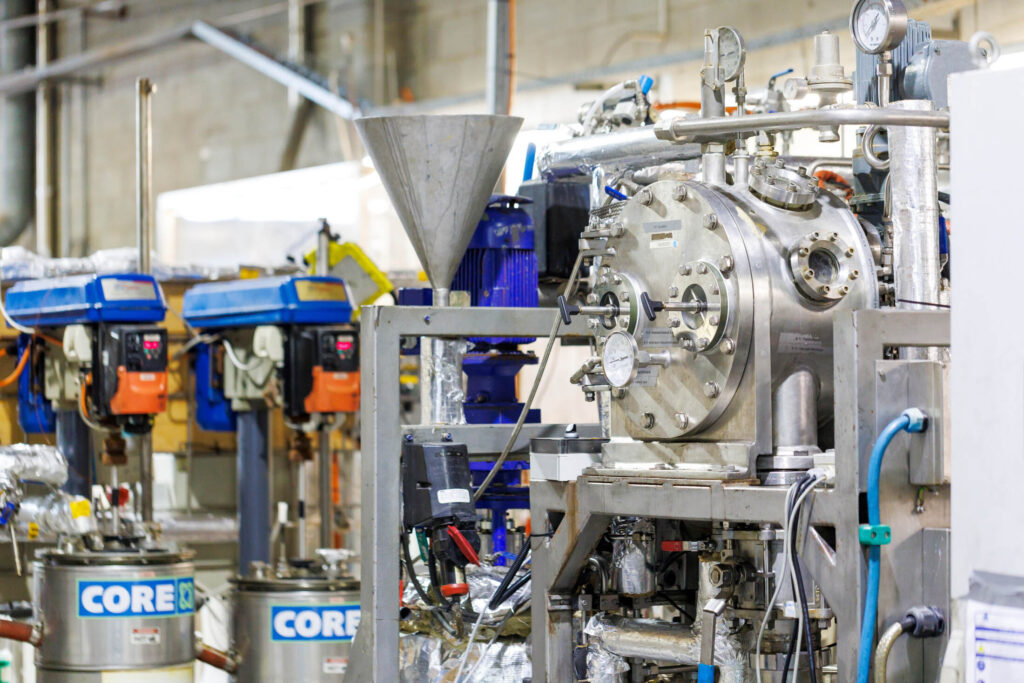

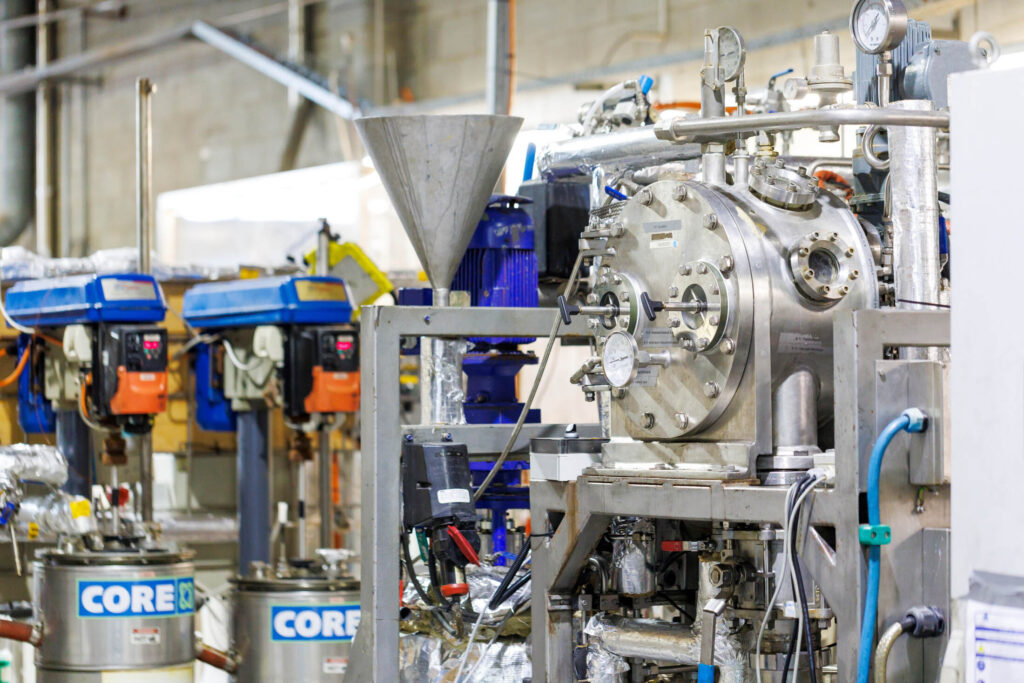

Pilot Plant Design

Core offers specialist design expertise to clients to ensure the right data is obtained during a pilot program. A process design package is prepared ahead of each pilot, forming the basis for key decisions in the design, construction, execution, sampling, scheduling and control of the pilot plant.

Core uses both METSIM modelling and a dynamic modelling (simulation) tool developed by our engineers to carry out evaluation and review of pilot flowsheets ahead of their construction. This is critical to the smooth operation of the pilot plant, and essential for ensuring reliable data is obtained.

Outputs from the METSIM and dynamic models also provide an accurate indication of process cycle times and the corresponding time required for the plant to reach steady state. This modelling step provides a robust way of identifying and demonstrating a feasible design and control strategy prior to commencing a pilot programme.

Execution & Process Control

Having full control of the processes and streams in a pilot plant are critical to its success. There are no second chances! Core specialises in maintaining precise control of pilot plants, even at very low flow rates.

Full digital monitoring capabilities are available on site via our AdamView data acquisition and display system.

This system brings live plant data (tank weights, temperatures, pH, torque etc.) to a central computer via an Ethernet network for display, recording and reporting.

If required, pilot plant data can be streamed live for secure remote monitoring by our clients.

Core’s technical staff are first class and well trained in the detailed requirements of operating pilot processes.

Having full control of the processes and streams in a pilot plant are critical to its success. There are no second chances! Core specialises in maintaining precise control of pilot plants, even at very low flow rates.

Full digital monitoring capabilities are available on site via our AdamView data acquisition and display system.

This system brings live plant data (tank weights, temperatures, pH, torque etc.) to a central computer via an Ethernet network for display, recording and reporting.

If required, pilot plant data can be streamed live for secure remote monitoring by our clients.

Core’s technical staff are first class and well trained in the detailed requirements of operating pilot processes.

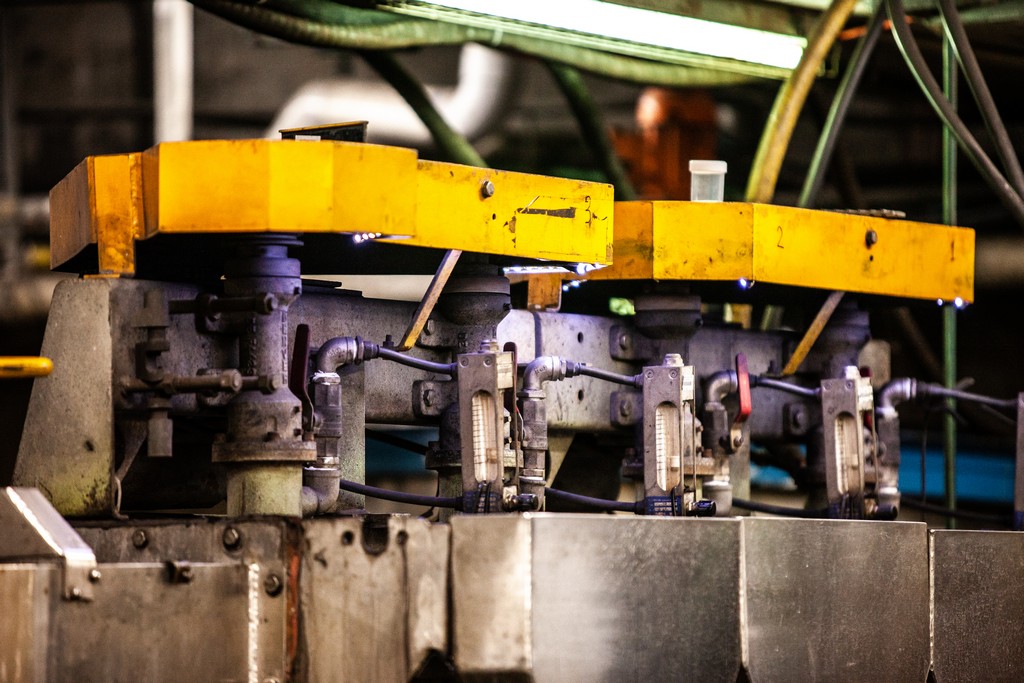

Construction & Mobilisation

No pilot is too simple or too complex! Core has an extensive inventory of equipment for use in pilot plant program and can mobilise pilot plants according to project requirements. Core has a dedicated pilot plant facility with all services available, and pipework and instrumentation installed.

Once equipment is mobilised, full commissioning is carried out ahead of execution. For hydrometallurgical pilots this will include a full water and slurry commissioning.

Analytical Support

Core’s on-site specialist development analytical laboratory supports pilot programs by providing very fast turnaround of assay results in-house, and specialist method development for difficult analytical matrices. The analytical laboratory is based on site alongside Core’s metallurgical laboratory. Pilot programs are able to obtain analytical data in as close to real time as possible.

For more on our analytical capabilities see the Analytical Services section.