Core Resources have recently been supporting the White Dam Gold Operation in South Australia. With Core’s assistance, GBM Resources is currently earning a 50% JV interest in project cashflows from existing owner Round Oak Minerals.

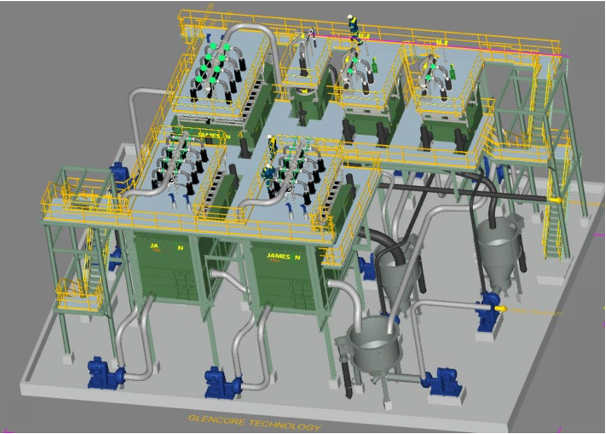

Mining has completed at site, and residual metals are being heap leached. High copper tenors are affecting gold leaching, and cyanide costs are extremely high. A low capital SART (sulphidisation, acidification, recycling and thickening) plant designed by Core is now being used to strip out and recover the copper and gold from process liquors, reducing cyanide consumption and enabling improved site rehabilitation. The advantages of the SART plant include:

• Reduction in extremely high cyanide additions to improve residual gold recovery;

• Removal of cyanide and copper from process liquors thus enabling a quicker and more effective shut-down;

• More complete extraction of residual gold and copper in the heaps;

• Potentially also allowing additional copper and gold resources from other regional sources to be economically

recovered

Civil works were completed in early 2020 and the SART plant construction was completed broadly as planned, with only small COVID-19 related delays to the delivery times of some key equipment. Staged commissioning activities commenced over the past three weeks as circuits in the plant were progressively completed. The circuit has now been continuously operated, with reagent additions and first copper sulphide concentrate having been produced. The gold leaching and SART plant are targeted to reach steady-state operations during the current quarter.

Please see GBM Resources’ latest press release on the successful start-up of the SART plant.

Want more information on the SART technology? Contact us at [email protected].