Metallurgical Testwork at Webbs Silver Project – High Silver Recoveries Achieved

Promising Results from Flotation Testwork

Silver Mines Limited (ASX: SVL) has reported highly promising results from recent metallurgical testwork at its Webbs Silver Project in northeastern New South Wales, Australia. Conducted by HRL Testing in collaboration with Core Resources, the program is being managed by Mineralurgy Pty Ltd, a leading metallurgical consulting firm. The testwork aims to optimise silver recovery while refining the flotation process to improve overall efficiency.

The results have been highly encouraging, with silver recoveries reaching 94% at a 75-micron grind and 92% at a 212-micron grind. The bulk sulphide concentrate produced from this process contained silver grades of up to 2,814 grams per tonne (g/t), a significant increase from the original head grade of 365 g/t. In addition to silver, the testwork also demonstrated high recoveries for other valuable metals, including copper and zinc, with recoveries of up to 91%. Lead recoveries reached 69%, further highlighting the potential of the Webbs deposit. Importantly, the flotation process has been shown to be effective even at relatively coarse grind sizes, which has positive implications for reducing energy consumption in the grinding circuit.

Testwork Methodology and Findings

The testwork was conducted using two 2-kilogram samples, each representing different grind sizes. These samples were taken from a 250-kilogram composite sample created from 160 drill core intersections at the Webbs Main Zone. The flotation process involved three rougher and two scavenger stages, with a final concentrate mass pull of around 12%.

Microscopic analysis of the sulphide minerals revealed that silver-bearing tetrahedrite grains were relatively coarse and could be effectively liberated through ultra-fine grinding. This is a promising finding, as it indicates that further processing could enhance the recovery and grade of silver and base metals.

Next Steps in Metallurgical Evaluation

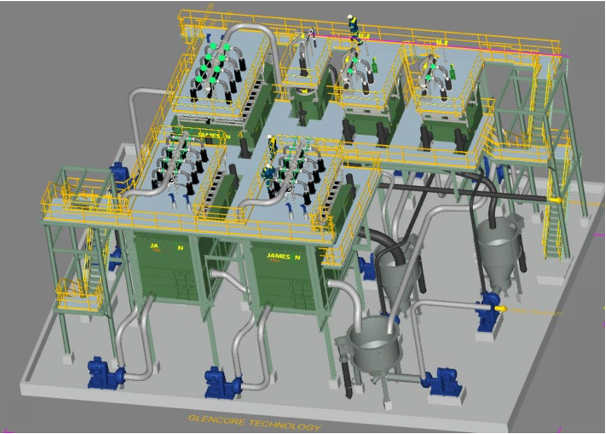

Following the success of this initial flotation testwork, larger-scale flotation is now underway to produce 10 kilograms of bulk sulphide concentrate. This material will undergo ultra-fine grinding and Albion/cyanide leach testwork to assess the potential for producing silver doré and base metal concentrates.

Further flotation optimisation studies will also be conducted to enhance metal recoveries and improve the overall quality of the final concentrate. By refining the processing methodology, the project aims to unlock the full economic potential of the Webbs Silver deposit.

Conclusion

These results confirm the strong economic potential of the Webbs Silver deposit, with an efficient and cost-effectiveprocessing route emerging from the testwork. As further evaluations continue, the project is expected to gain greater clarity on the most effective metallurgical approach for maximising silver and base metal recoveries.

Download the company announcement here.