Core Resources has developed an innovative sampling method to enhance the accuracy of process control in autoclave operations. This advancement addresses the challenges associated with traditional sampling techniques in high-pressure autoclave environments.

Challenges with Traditional Sampling

In autoclave processes, such as Pressure Oxidation (POx) and High Pressure Acid Leaching (HPAL), obtaining accurate samples is crucial for effective process control. Traditional sampling involves “flashing,” where a valve releases high-pressure slurry rapidly, causing immediate changes in temperature and pressure. This rapid transition can significantly alter the sample’s chemistry, leading to inaccuracies in measuring parameters like redox potential and ionic concentrations.

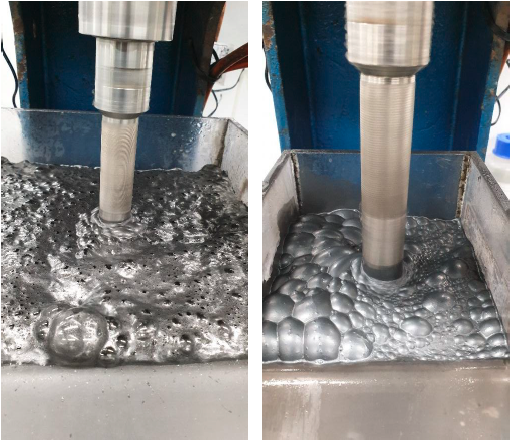

Innovative Sampling Method by Core Resources

To overcome these challenges, Core Resources developed a custom-designed sampling bomb that allows slurry samples to be taken and filtered while maintaining the autoclave’s internal pressure. This method ensures that the samples reflect the actual conditions within the autoclave, providing more accurate data for analysis.

Impact on Process Control

Implementing this new sampling technique has led to significant improvements in process control for autoclave operations. In comparative tests, parameters such as Oxidation-Reduction Potential (ORP) and ferrous/ferric ion ratios showed differences of up to 25% between traditional flashing methods and the new sampling approach. These more accurate measurements enable operators to optimise autoclave performance, enhancing production efficiency and throughput.

Future Applications

Core Resources plans to apply this sampling method to other processes, including at-pressure sampling of precipitation and crystallisation systems. This could lead to a better understanding of the chemistry involved in these systems, further improving process control and efficiency across various mineral processing operations.

This advancement exemplifies Core Resources’ commitment to innovation in metallurgical testing and process optimisation, providing clients with reliable data to enhance their operations.