Ion Exchange Solutions for Vanadium and Base Metal Recovery

Together with IPEX, Core provides Ion Exchange solutions for Vanadium, base metal recovery and tailings applications.

Ion exchange is a process typically used extensively in the wastewater industry that has wide ranging application in the mining industry to recover valuable metals from solution.

The principle of ion exchange for mining applications is that certain dissolved metals in solution can be selectively recovered onto a targeted resin over other dissolved elements in solution. The recovered metals can then be stripped off the resin by contact with acid or alkali to generate a concentrated, purified, metal solution stream for further processing to saleable products.

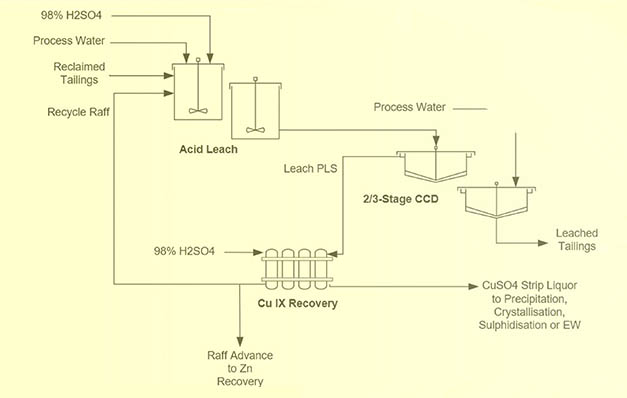

Example in practice – Copper, a high value metal, can be recovered from process or

tailings water in copper mines by using a chelating IDA resin such as Lanxess Lewatit MonoPlus TP 207.

This resin is highly selective for Cu2+ over many other typical elements in mining process waters (see below selectivity order). Very high recovery of Cu from solution can be achieved, down to discharge concentrations of 2-10 mg/L.

The Cu can then be stripped off the resin with sulphuric acid to generate a concentrated copper sulphate solution which can be processed to various end products. Feed Cu tenors as low as 25 mg/L can be processed via Ion Exchange, which makes IX suitable for tailings and process water scavenging applications.

Lanxess Lewatit MonoPlus TP207 Ion Selectivity Order

Fe3+ > Cu2+ > (VO)2+ > (UO2)2+ > Pb2+ > Ni2+ > Zn2+ > Cd2+ > Fe2+ > Mn2+ > Ca2+ > Mg2+ >> Na+

Ion exchange is a process typically used extensively in the wastewater industry that has wide ranging application in the mining industry to recover valuable metals from solution.

The principle of ion exchange for mining applications is that certain dissolved metals in solution can be selectively recovered onto a targeted resin over other dissolved elements in solution. The recovered metals can then be stripped off the resin by contact with acid or alkali to generate a concentrated, purified, metal solution stream for further processing to saleable products.

Example in practice – Copper, a high value metal, can be recovered from process or tailings water in copper mines by using a chelating IDA resin such as Lanxess Lewatit MonoPlus TP 207.

This resin is highly selective for Cu2+ over many other typical elements in mining process waters (see below selectivity order). Very high recovery of Cu from solution can be achieved, down to discharge concentrations of 2-10 mg/L.

The Cu can then be stripped off the resin with sulphuric acid to generate a concentrated copper sulphate solution which can be processed to various end products. Feed Cu tenors as low as 25 mg/L can be processed via Ion Exchange, which makes IX suitable for tailings and process water scavenging applications.

Lanxess Lewatit MonoPlus TP207 Ion Selectivity Order

Fe3+ > Cu2+ > (VO)2+ > (UO2)2+ > Pb2+ > Ni2+ > Zn2+ > Cd2+ > Fe2+ > Mn2+ > Ca2+ > Mg2+ >> Na+

Project Experience

Core has project experience in the following key applications:

- Removal/recovery of dissolved metals selectively from process solutions. Example metals which have been demonstrated to be recovered via IX include nickel, cobalt, molybdenum, manganese, zinc, copper, vanadium, uranium and gallium.

- Purification of process solutions via removal of trace impurities. For example, Sb and Bi removal from copper electrolyte, or earth alkali (Ca, Mg) removal from lithium solutions.

- Desalination of process solutions, for example acid mine drainage (AMD) treatment.

- Substitution for solvent extraction applications, particularly with dilute solutions.

Testwork Capabilities

Core has the equipment and expertise to facilitate both batch and continuous IX testing and piloting:

- A library of ion exchange resins stored on-site. Additionally, relationships with resin suppliers allow for project-specific manufacturer resin recommendations and provision of resin samples for testing.

- Glassware and stirring equipment to run resin shake-out tests for up front resin screening tests.

- Custom fabricated acrylic ion exchange columns, from 20 mm to 50 mm ID. Columns can be operated in downflow or up flow with fluidised bed, at 500 mL/h to 5 L/h influent flow rates.

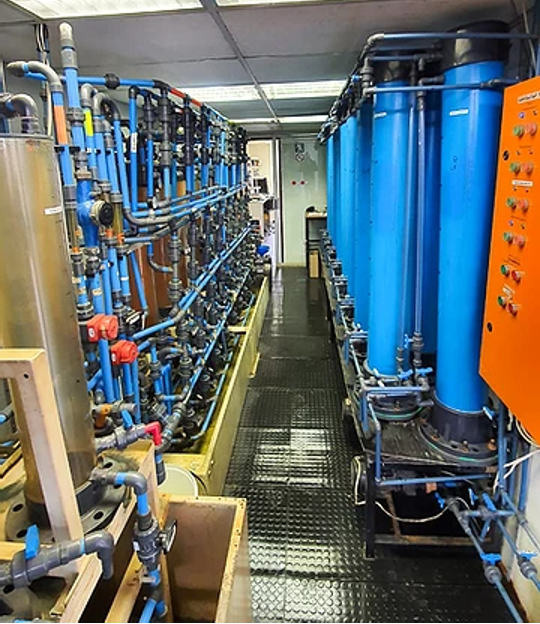

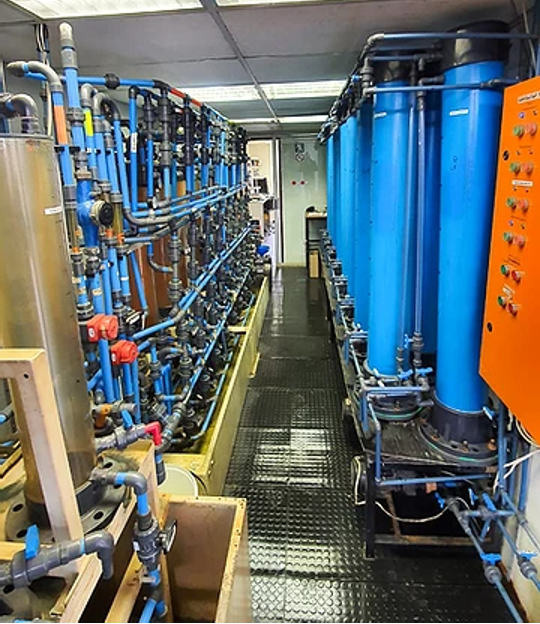

- Pilot-scale IX rig (pictured above), supplied by X GROUP, capable of up to 60 L/h influent flow rates. The rig consists of four 200 mm ID IX columns connected in series, allowing batch-continuous operation of a lead-lag-polishing 3-stage loading regime, with the fourth column offline for washing and stripping.

Flowsheet Development through to Installation and Commissioning

Core has entered a joint venture with X GROUP, forming Core IPEX. This gives Core access to the vanadium ion exchange expertise and technologies developed by the X GROUP for producing high purity vanadium products, such as vanadyl sulphate and ammonium metavanadate. Core IPEX can design, construct and commission ion exchange plants and X GROUP currently run a continuous Vanadium IX production plant in South Africa from fly ash waste.

Through the Core IPEX joint venture, Core has access to the X GROUP’s engineering and manufacturing capabilities, as well as their strong operational experience. Core IPEX can take an IX project from proof-of-concept stage to engineering, manufacturing, commissioning and provide operational support. X GROUP can manufacture modular containerised IX plants in South Africa which reduce installation and commissioning time and costs.

Installations

Three key examples of IX plants built and operated by X GROUP are as follows:

- Built, own and operated a 1.8 ML/day IX and heap leach plant producing a liquid V intermediate product from calcine tailings. The plant was operated from 2006 to 2010.

- Retrofitted a redundant IX plant to allow brineless sodium cycle softening of 10 ML/day dolomitic fissure water to a potable standard. Plant has been operating since 2013 under Sibanye Ltd.

- Built, own and currently operate a 1.6 ML/day IX and heap leach plant producing a liquid V intermediate product from calcine tailings. IX plant is a modular containerised unit, demonstrating X GROUP’s capacity to produce simple to install and commission modular IX plants. Plant has been operating since 2017.

Ion exchange has a wide range of applications for metal recovery and purification in hydrometallurgical flowsheets. Core can assist with any aspect of ion exchange, from evaluation of target tailings ponds to configuration of ion exchange unit operations within hydromet flowsheets.