Core Process Engineering continues flowsheet development work and is now preparing capital and operating cost estimates to Scoping Study level to evaluate a 500,000 tonne per year processing facility, capable of producing up to 4Moz of silver per annum for the Webbs Silver Project.

View the announcement here or read the summary below:

Webbs Silver Project Achieves Over 90% Silver Recovery in Metallurgical Testwork

Significant Progress in Silver Recovery

Silver Mines Limited (ASX: SVL) has announced outstanding metallurgical testwork results for its 100%-owned Webbs Silver Project in New South Wales, Australia. The latest findings indicate that more than 90% of silver can be recovered into doré bars, marking a significant step forward in the project’s development.

High Silver Recovery Rates Through Advanced Processing

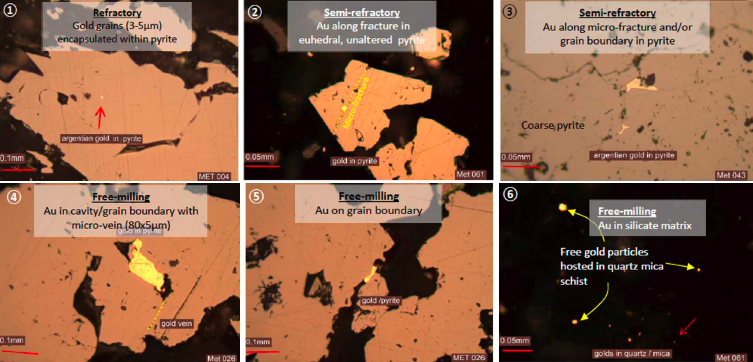

The testwork began with bulk sulphide flotation at a relatively coarse grind size of 212 microns. This initial stage successfully recovered 95.9% of silver into a 12% mass pull concentrate, which assayed at 2.2 kg/t Ag. The concentrate also contained valuable copper, zinc, and lead.

Following this, the concentrate was subjected to the Albion Process™, involving ultra-fine grinding to a size of 80% passing 8.5 microns. The material then underwent oxidative alkaline leaching, which demonstrated rapid leach kinetics with less than 60% of total sulphur requiring oxidation. The leach residue was subsequently treated with conventional cyanidation, achieving an impressive 98.4% cyanide-soluble silver recovery.

Collectively, these processing steps yielded an overall silver recovery of 94.3% into the cyanide solution. While the final stage of silver recovery into doré has yet to be tested, the well-established Merrill-Crowe process is the preferred method. Based on its proven efficiency in commercial operations, this process is expected to recover more than 95% of the silver from the cyanide solution, leading to an overall silver recovery exceeding 90% into doré bars.

Ongoing Optimisation and Future Testwork

Further testwork is underway to optimise key processing parameters, with a focus on:

- Refining the balance between mass pull and silver recovery to achieve a mass pull of less than 10% while maintaining silver recovery above 95%

- Further process optimisation to establish the best grind size, leach conditions, and sulphide oxidation parameters for the Albion Process™-Cyanide Leach-Merrill-Crowe flowsheet

- Investigating options for recovering zinc and copper concentrates after the Albion leach stage

- Expanding testwork to include composite samples from the Webbs South deposit to ensure consistent recovery rates across different ore zones

- Developing capital and operating cost estimates for a potential Albion plant at Webbs, capable of processing 500,000 tonnes per year

Cleaner Flotation Testwork Insights

Additional flotation cleaner testwork has been carried out to reduce non-sulphide gangue in the concentrate while decreasing the overall mass pull. Carried out on bulk sulphide concentrate at a 212-micron grind size, the results showed that reducing the mass pull slightly decreased metal recovery. However, the goal remains to achieve 95% silver recovery with a mass pull below 10%, which will require further refinements in grinding and flotation techniques.

The Role of the Albion Process™

Developed in 1993 by MIM Holdings (now part of Xstrata Plc), the Albion Process™ is designed to treat concentrates from refractory base and precious metal ores. It involves a hot oxidative leach of finely ground concentrates under atmospheric conditions, facilitating efficient metal recovery.

Conclusion

The latest metallurgical testwork at the Webbs Silver Project reinforces its strong potential for achieving high silver recovery rates exceeding 90% into doré bars. With ongoing process optimisation and further testwork planned, these results demonstrate the effectiveness of modern metallurgical processing techniques in improving silver recovery and highlight Webbs as a promising silver project in New South Wales.