Site Based Ore Sorting Trial

An Australian copper producer recently approached Core to assist with an on-site project for trialling Ore Sorting equipment. The goal of the trial was to investigate sorting as a technology to upgrade an existing large stockpile of low grade ore to prepare it for flotation.

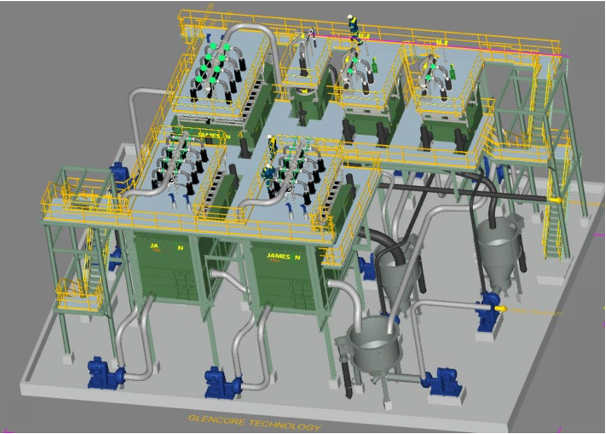

The trial was conducted on site, and included the trial installation and full scale operation of the Ore Sorter next to large ROM heaps at the operation. The Ore Sorter used was a STEINERT XSS T (x-ray transmission) model. The technology was employed to analyse ore moving on a conveyor belt, with low grade material rejected by an air expulsion system as the material reached the end of the belt.

Core was engaged to manage the whole project on site. Lachlan MacDonald, Principal Process Engineer at Core, was deployed residentially on site for 2 months to commission, operate, debug and optimise the operation of the sorter. The programme was designed and managed by Core. Operational parameters such as particle size, throughputs and ore sorter calibration were evaluated to determine the optimal operating conditions with respect to product grade, copper recovery and throughput. Specific results from the trial are confidential.

Core also provided support engineering and input into techno-economic evaluations. A process model was developed by Core to assist with fast tracking development of operational parameters for subsequent ore types. Core provided key input into the financial model, to develop the cost/benefit analysis of the installation.

Core also provided on-site training of technicians, development of best operating practice documentation to assist the site in ongoing use and maintenance of the equipment.

Key to the success of this project is the flexibility, quality and experience of senior engineering staff available at Core. Lachlan was able to step into a site based role seamlessly and immediately provide quality professional and technical leadership to this project. A proactive approach meant that major hurdles and bottlenecks were raised early with corporate management, and solid technical solutions proposed and identified.

The outcome for the client was very significantly improved quality of data, enabling the operation to make an evaluation of the proposal for long term installation of the sorter. This was achieved with a major site based trial with zero safety incidents. It is a great example of the way Core works in collaboration with our site based clients, to enable them to achieve their technical goals sooner and more cost effectively.