Core is delighted to announce that it has been awarded funding from the Queensland Government’s Advance Queensland Ignite Ideas Fund Round 5 for the continued development of its innovative Toowong Process. The Ignite Ideas Fund supports Queensland based start-ups and small to medium Queensland businesses to commercialise innovative products, processes and services to enable them to grow and compete in a global market and create new jobs. This funding will help to further accelerate Core’s fast-tracked development process.

About Core

Core is a metallurgical processing innovation company. Core’s vision is to change the way the world produces minerals so that future processing is clean and sustainable.

With a reputation for innovative clean process technologies, Core has pursued commercialisation of its novel technologies and expansion of its expert service offering to the global mining industry. One of its technologies, the Toowong Process, is being commercialised to address the global environmental problem of hazardous contaminants which are frequently contained in mineral concentrates produced by mines.

Core has worked with companies in more than 50 countries, bringing Australian expertise and technology to the world.

The Technology

Core’s Toowong Process is a revolutionary technology which removes hazardous contaminants from base metals concentrates; and “fixes” these contaminants in an environmentally stable and manageable form. This addresses a major global environmental problem for which there is currently no other effective solution.

Worldwide, tens of thousands of tonnes of highly toxic arsenic are transported as contaminants in base metals concentrates. This is shipped from mines to smelters, which are often located in highly populated industrialised areas. Without removal, this arsenic poses a major global environmental and health problem. Nearly 10% of the world’s copper concentrates are currently too contaminated with arsenic for safe use and many countries of import now enforce strict limits on the levels of such contaminants in imported concentrates.

For example, it is estimated that 12% of China’s agricultural land is now too contaminated from metallurgical effluents to be safe for use [1].

The Toowong Process enables the safe and hygienic removal of this arsenic at source, and it converts it into a stable and non-toxic form for safe disposal. The treated mineral concentrate product can then be shipped in a clean, safe form.

Technology Status

The Toowong Process is at an advanced stage of development. It is expected to be operationally ready after current phases of work, which comprise detailed process design and further pilot plant studies.

Following a global Expressions of Interest process earlier this year, Core has partnered with a highly qualified collaborator in this development work. In conjunction with the Ignite Ideas funding, this will secure an aggressive development program.

Engineering design and costing work undertaken recently demonstrates that the Toowong Process has very attractive economics. Operating costs are less than half of the penalty charges that producers would otherwise have to pay to be able to sell their “dirty” concentrates.

For miners, having an effective solution to arsenic contamination also means they can run their mine in an optimised manner, without the constraints that would be imposed by having to meet arsenic limits. This can add years to mine life and bring significant value to a project.

The Copper Concentrates Market

The increasing challenge of rising arsenic levels at a time of ever-increasing environmental controls is well recognised in the marketplace:

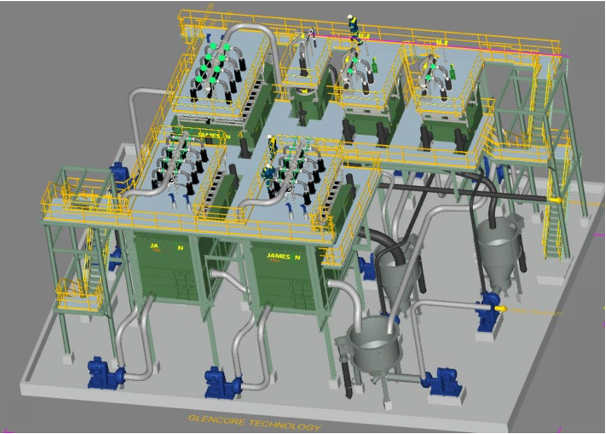

“Glencore PLC has opened a new blending plant in Taiwan to prepare potentially hazardous copper ores for smelting amid a surge in high-arsenic material hitting the market, according to people familiar with the matter.” [2]

“China’s customs agency has held discussions with the country’s major copper smelters with the aim of creating stricter limits on impurities contained in imported copper concentrates…….The focal point of discussions was to lower the current 0.5% limit on arsenic contained in imported copper concentrates to 0.4%, the sources said.”[3]

“A study….estimates that high-arsenic concentrate now constitutes 8% of total global supply. This will increase to 9% as a base case by 2028 but could potentially grow up to 13% by that time, the study said.” [4]

For more information please contact:

Dr Rob Coleman, CEO, Core Group, Australia

[1] The Economist, 2017

[2] Bloomberg, July 2019

[3] Metal Bulletin, August 2019

[4] “Arsenic: Will it take the shine off the red metal?” MineSpans by McKinsey, August 2019