Fluorine, the 13th most abundant element in the Earth’s crust, has become a significant concern in metallurgical processing, especially as mining projects increasingly encounter marginal or ‘dirty’ ores. Elevated fluorine levels in mineral concentrates can lead to substantial environmental damage during smelting and result in heavy financial penalties if concentrations exceed acceptable limits in products sold to smelters.

Accurate fluorine analysis is crucial for effective management of mineral processing and the sale of concentrates. Traditional methods, such as Ion Selective Electrode (ISE), are often labor-intensive, require high skill levels, and are susceptible to various interferences.

Fluorine analysis is traditionally labour intensive which requires a high skill level and has many interferences. Our HPLC overcomes most of these issues providing accurate results with a robust method that is suitable for a wide range of sample types. Geoff Whebell – COO

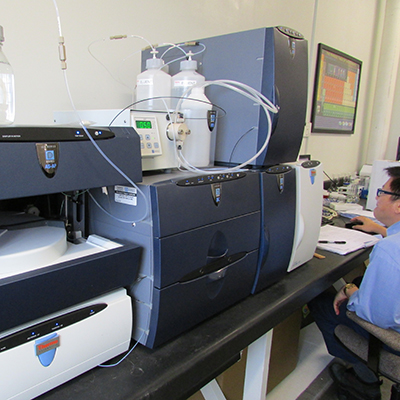

In response to these challenges, Core Resources has developed a robust method for fluorine analysis using a university-grade High Performance Liquid Chromatograph (HPLC). The Dionex ICS5000 instrument employed in our metallurgical testing laboratory is one of only 12 in Australia and the sole unit in a commercial laboratory. HPLC systems are instrumental in determining anions and cations in solids and solutions.

Our HPLC system features a neutralisation unit and eluent suppressor, offering an advanced analytical technique for fluorine analysis in copper concentrate samples. The neutralisation unit adjusts the alkaline sample solution before injection into the instrument’s analytical column.

Our HPLC system involves only one single step of sample injection after sample fusion. Therefore, we can deliver highly accurate results much faster than other methods. Pau Chieng – Technical Manager

This suppressor and neutraliser technology eliminates the need for manual pH buffering, a time-consuming preparation step in traditional ISE methods. It also overcomes matrix interferences from copper, commonly encountered in the analysis of copper concentrates. The method developed provides fast, robust, and accurate fluorine analysis, even at low levels.

We have successfully tested water samples <5ppm F, low level Fluorine in concentrates and ores 0.01-0.42% all the way up to spec pure Fluorspar of up to 48% F. Phil Whittle – Lab Manager

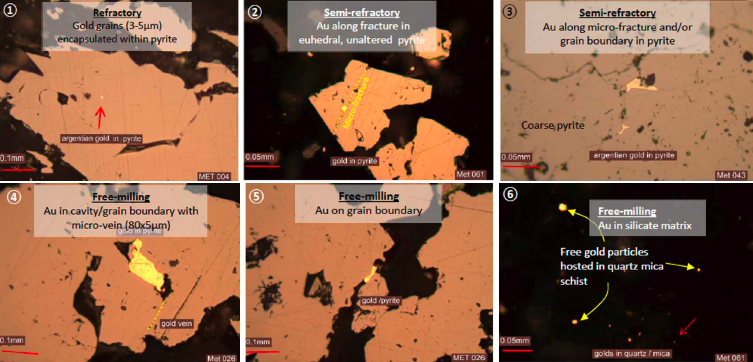

Several processing options are available to reduce excessive fluorine levels in the production of concentrates, including:

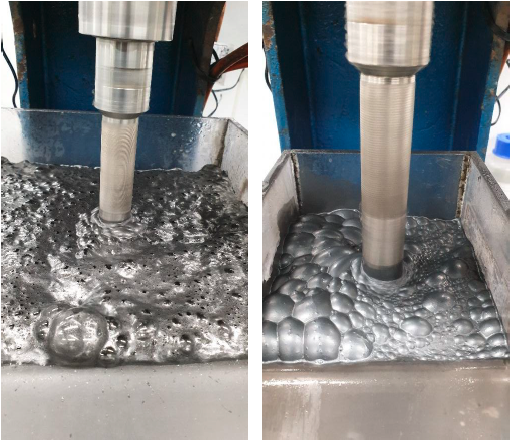

- Removal of fluorine-containing minerals by flotation using depressants

- Selective leaching of fluorine minerals

- Selective leaching of copper minerals

All these processes can be evaluated at Core Resources. Accurate analysis and metallurgical balancing are critical in any of these processes.

Our metallurgical testing services encompass R&D and piloting capabilities, supported by high-quality testing instruments and processes necessary to collaborate with clients on emerging technologies. We prioritize setting the highest testing standards while safeguarding our clients’ intellectual property.

We offer this analytical technology as part of metallurgical testwork programs conducted at our facilities or as a site support service for operations managing fluorine issues in their processes. For further enquiries, please feel free to contact us and we will be happy to help.