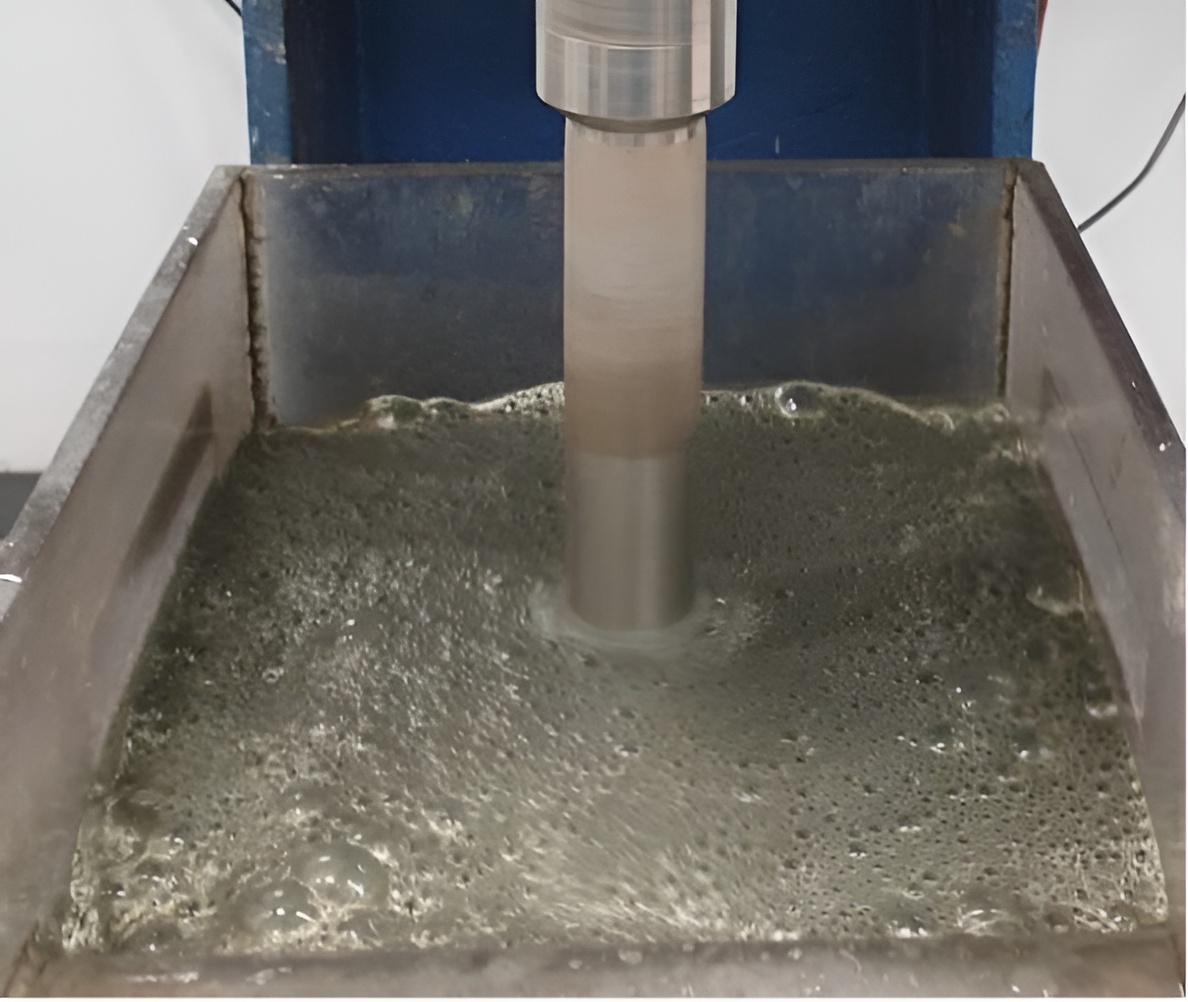

Core Resources has officially opened a dedicated flotation laboratory at its Brisbane facility, marking a significant enhancement to its metallurgical testing and process engineering capabilities. This expansion consolidates all flotation testwork equipment–including mills, flotation cells, filters and particle sizers–into a single, state-of-the-art space, streamlining workflows and increasing testing capacity.

With over 150 years of combined flotation expertise, Core Resources offers comprehensive services encompassing testwork design and execution, flowsheet development, modelling and simulation, full plant design and layout, equipment sizing and selection, as well as flotation plant engineering and scoping and pre-feasibility studies.

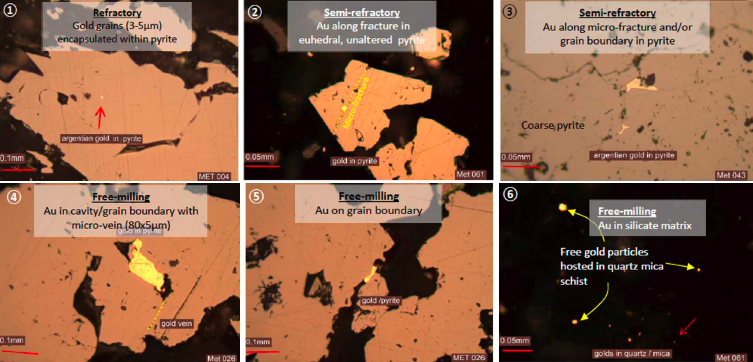

The new laboratory is equipped to conduct bench-scale, locked cycle and pilot-scale testwork, along with geometallurgical and future ore testing. This enables the development of optimised flowsheets based on empirical data, facilitating informed decision-making for clients.

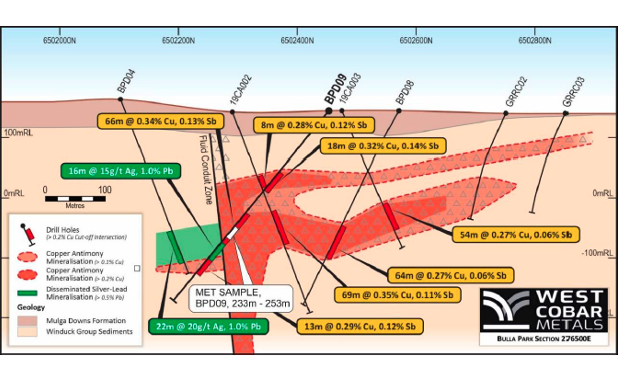

Core Resources has a proven track record of successful project development across various commodities, including base metals, precious metals, battery metals and industrial minerals. The company’s expertise extends to reviewing the performance of existing operations, providing site-based expertise in commissioning, plant operations and optimisation.

This laboratory upgrade underscores Core Resources’ commitment to delivering high-quality flotation testing and innovative solutions to complex metallurgical challenges.

For more information or to discuss your flotation testing requirements, please contact Core Resources at [email protected].