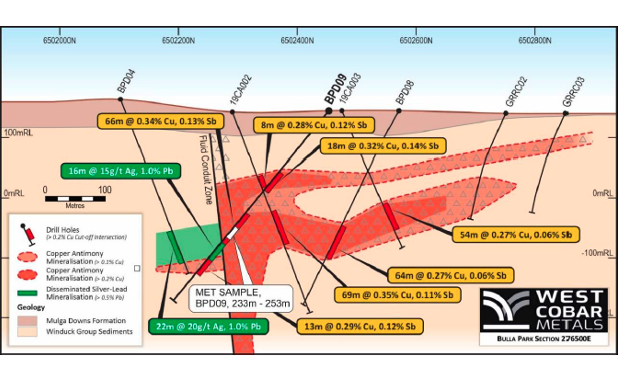

The mining industry faces increasing challenges with rising levels of arsenic, antimony, and other contaminants in base metal concentrates. Stricter regulations on the shipment, import and treatment of these contaminated concentrates, coupled with a diminishing supply of clean concentrates for blending, have intensified the need for effective solutions.

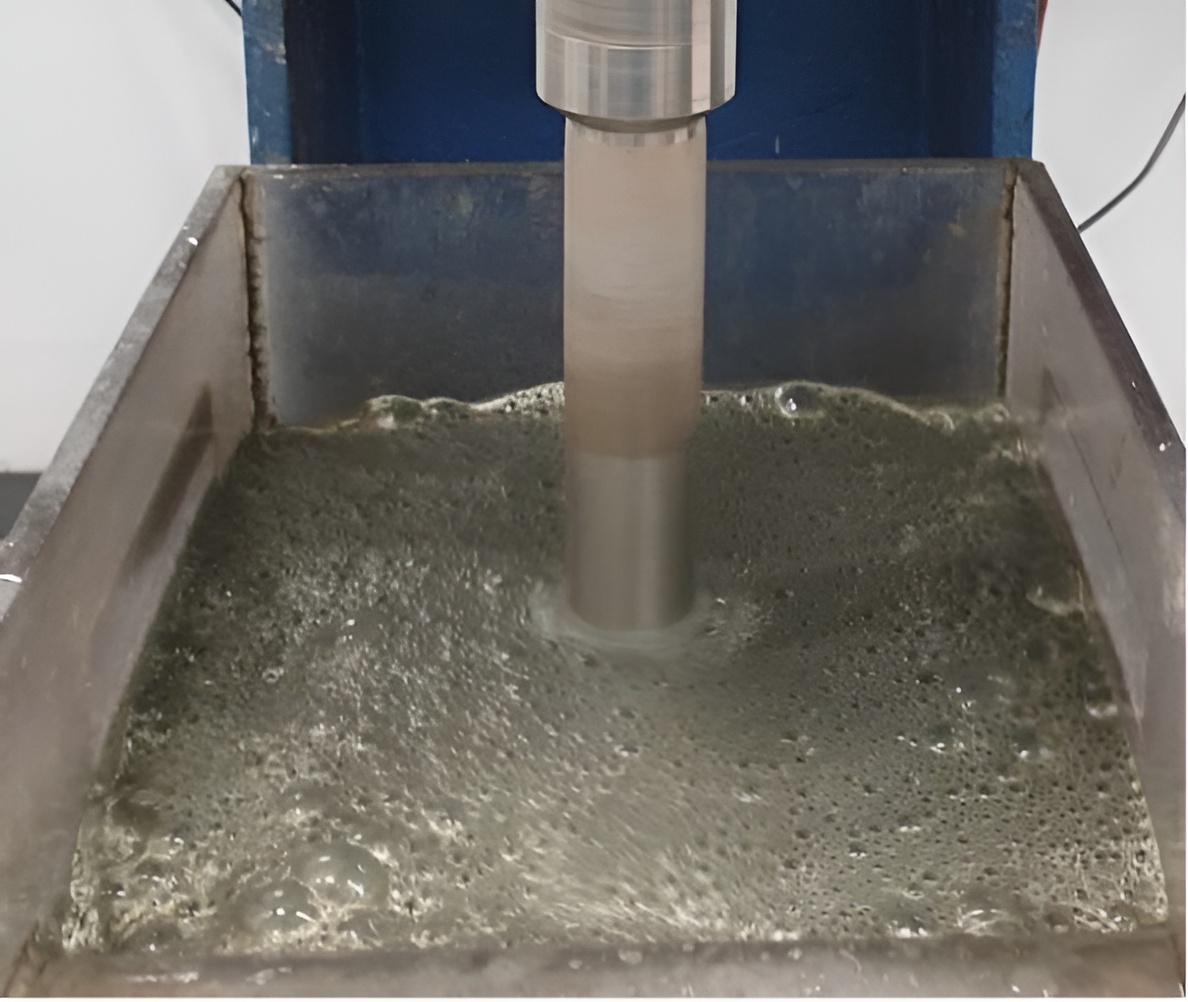

In response, Core Resources has developed the Toowong Process™, an integrated hydrometallurgical method designed to selectively remove contaminants from concentrates and safely dispose of residues in an environmentally stable manner. Advancements in process development have led to substantial cost reductions, enabling arsenic removal costs to produce a clean copper concentrate to be as low as 15 cents per pound of saleable copper. This efficiency has garnered interest from miners, smelters, and commodity traders worldwide.

The Toowong Process™ offers a transformative approach to managing impurities in base metal concentrates, providing a viable solution to a complex global challenge. Core Resources continues to welcome inquiries from parties interested in evaluating this innovative technology.