In the ever-evolving landscape of the mining industry, the quest for sustainable and innovative solutions to mine waste management is more pressing than ever. Core’s pioneering approaches and commitment to environmental stewardship are at the forefront of this revolution.

Core’s Jon Loraine was interviewed by iQ Industry Queensland at the recent Australian Mine Waste Symposium. His insights into the challenges and opportunities facing the industry today are not just thought-provoking but are a beacon of hope and innovation for a sector that is crucial to our global economy and environmental future.

Jon’s conversation sheds light on the ‘new horizon’ of research and thinking being applied to tailings dam remediation. With a focus on retreating for remnant minerals, reducing tailings generation through advanced processing techniques, and the potential for reusing tailings.

Read the full interview here:

Stars aligning for a dedicated tailings processing industry

The head of one of the most experienced metallurgical engineering houses in the country has praised the ‘new horizon’ research and thinking being applied to tailings dam remediation.

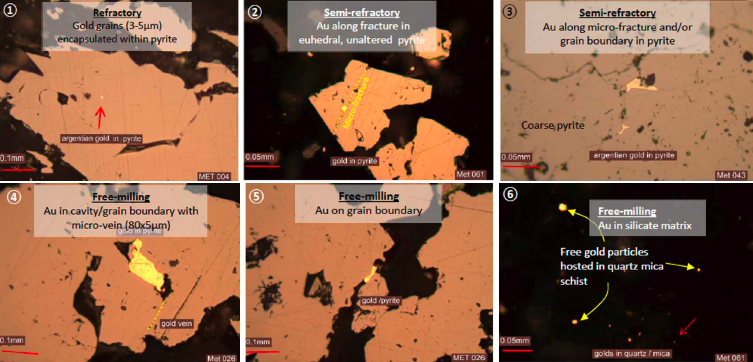

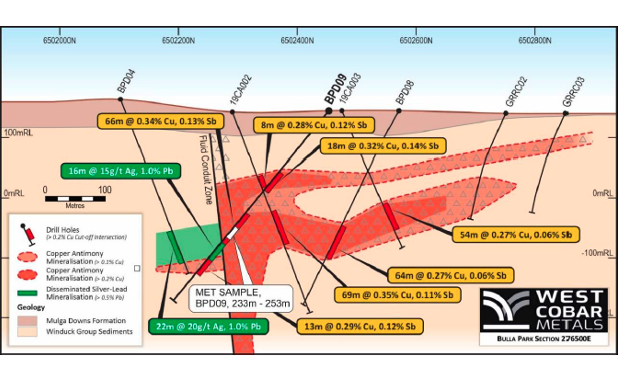

Some are talking about retreating for the remnant minerals; some are focused on processing so less tailings are generated; and some on reusing tailings.

The challenges had more to do with complex processing than mining, said company founder and chair of Brisbane-based Core Resources Jon Loraine, who spoke at the recent Australian Mine Waste Symposium.

The goalposts had changed to encourage tailings treatment, in some cases by virtue of technology and in others due to market forces, Mr Loraine said.

There were other influences, he said.

“I think there’s a very good incentive and activity from government supporting this for good reasons. The other thing is major mining corporations, it’s become really front of mind to them.

“If you look at a multinational like BHP or Rio Tinto, one of the very few things that can seriously damage them as an organisation is a big environmental or tailings problem.

“So, they take it very seriously and you’re seeing them putting serious money into producing less tailings and managing tailings properly and extracting full value from tailings materials.”

He agreed with the tenet that the best time to treat tailings was when the mine was running and the second best was when the mine had stopped and the run of mine was still operable.

“So anything that allows maybe a third party even to work on a mine site while it’s still running to retreat and recover residual metals is a great idea,” he said.

“As we’ve seen from some of these case studies, it gets much more difficult years later when all the infrastructure is gone, which is expensive to replace, and often the facilities deteriorate, the tailings weather and it’s just a much harder task if you come back 20 years later.

“So I do think there’s a number of things that could be done at a legislative level to really enable tailings to be looked at more actively.”

Tailings characterisation was the other effective effort which could be introduced earlier into the process, Mr Loraine said.

“To some extent it holds the mining company more accountable, which is not a bad thing. It also makes that information available to third parties who may be interested in coming in, doing something with it.

“So that would be a very simple way of making it a lot more transparent what’s going into tailings and it is something that really should not be difficult from a legislative or workload point of view.

“Honestly, it would be a very enlightened thing to do. It would really show Australia leading the way in this whole issue of managing mine waste and residues.

“Look at the opportunities that it will encourage third party to come in and have a go and have a look at retreating these materials.”

Regulation would need to be considered to allow a third party on an operating lease to conduct commercial activities like retreatment, Mr Loraine said.