Dr Rob Coleman, CEO of Core Resources, was recently interviewed by The Rock Wrangler to discuss the role of early metallurgical testing in developing technically and commercially viable critical minerals projects. What follows is a reprint of that article, which explores Rob’s insights into how Core is helping miners bridge the gap between lab results and real-world outcomes.

How early-stage metallurgical testing is helping critical minerals projects address complexity, reduce risk and support real-world process design

As critical minerals projects advance in complexity and urgency, early-stage metallurgical testing is no longer a “nice to have”—it’s a gatekeeper to technical and financial viability. For Dr. Rob Coleman, Chief Executive Officer of Core Resources, this shift is long overdue.

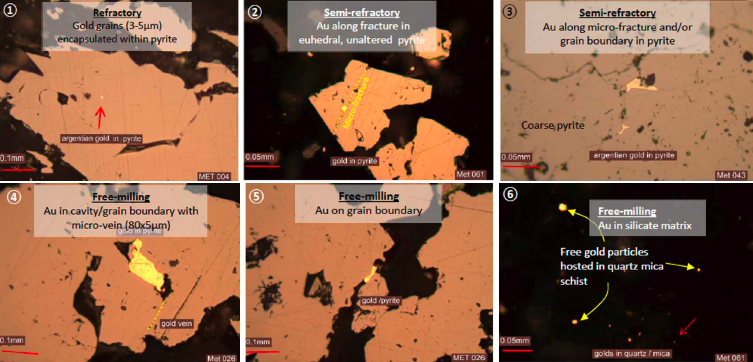

“Metallurgy has become more important as we treat more complex ores and develop ‘non-mainstream’ minerals,” Rob explains to The Rock Wrangler. “This is especially true for critical minerals, where the greatest project risk lies in processing. You simply can’t determine if a project is viable without understanding how to process the ore—and you need to do that early.”

Based in Brisbane, Core Resources is an integrated metallurgical testing and process engineering company known for bridging the lab-to-plant divide. Its reputation is anchored in the company’s ability to design and execute metallurgical testwork programs that don’t just provide results—they provide answers.

Early-Stage Testing That Saves Time and Capital

For Rob, early testing is no longer about lab curiosity—it’s about project survival. “We’re seeing a greater emphasis on early-stage testwork, particularly to inform process flowsheet development,” he says. “If you can’t prove that the project will be technically and commercially viable, you can’t justify further investment.”

This is where Core stands apart. Unlike traditional labs, Core brings operations experience to the design of every program. “We’re not just testing something in a flask,” Rob explains. “We’re asking: Can this be constructed in the field? Will it work in a remote location with limited operator skill? Is it maintainable? Safe? Hygienic? That operational grounding is embedded in everything we do.”

It’s a pragmatic ethos that resonates with juniors and mid-tiers trying to stretch limited budgets while attracting serious investors. “A large proportion of our clients are explorers. We design early testwork to develop an initial flowsheet, then provide cost/value trade-off studies to determine viability. If it passes that first gate, we move on to a more comprehensive program.”

This staged approach avoids costly mistakes. “It allows fatal flaws to be identified early,” Rob says. “Better to find out now than after you’ve sunk $20 million.”

Testwork with a Real-World Focus

One of the major advantages Core offers is the ability to design and execute testwork without relying on the mining company or its consultants to define every detail.

“Thanks to our in-house team of experienced metallurgists and process engineers, we can scope, design, and carry out the entire testwork program,” says Rob. “Our aim is to deliver the data needed in as few tests as possible, then use that data to build a practical flowsheet.”

That focus on real-world outcomes is what bridges the gap between testing and implementation. “The question is always: Will it work at full scale? That’s what drives our methodology.”

Addressing Variability and Risk

One of the most common pitfalls in flowsheet design is using unrepresentative samples. Rob doesn’t mince words: “The whole issue of representativeness and variability is often overlooked—and that’s a serious risk.”

As a project progresses from preliminary to definitive studies, that risk becomes critical. “By the time you’re at DFS or FS stage, variability testing is a must. Financiers won’t consider a project without testwork from multiple locations in the mine plan,” he says.

Simulation also plays an important role—particularly for hydrometallurgical flowsheets involving temperature, pressure, or complex reactions. “Simulation tools are widely used, especially in later stages, to understand how a system will behave. It helps refine designs before committing capital.”

Innovations That Matter

Core’s approach to innovation is refreshingly grounded. Rather than chasing hype, the company invests in process improvements that directly impact project viability—particularly for hydrometallurgical systems, which are increasingly used to process complex and low-grade ores.

Rob highlights several examples. “We’ve developed and commercialised the Toowong Process™, which removes arsenic from copper concentrates in a closed-loop system that recycles expensive reagents and eliminates toxic effluent build-up. That’s been a 15-year journey, but it’s now in the final stages of commercialisation with a major resources group.”

Other innovations include collaborative work with:

- Glencore Technology on the Albion Process™;

- The X-Group on ion-exchange technologies for vanadium recovery;

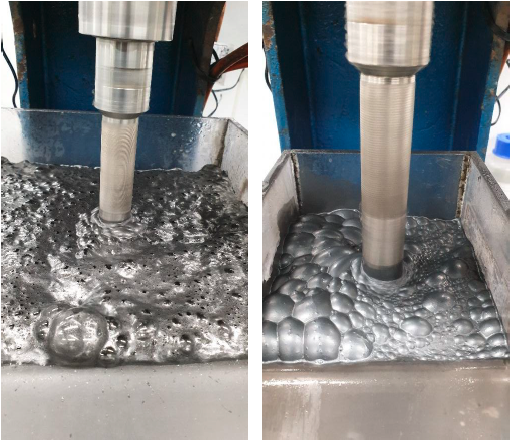

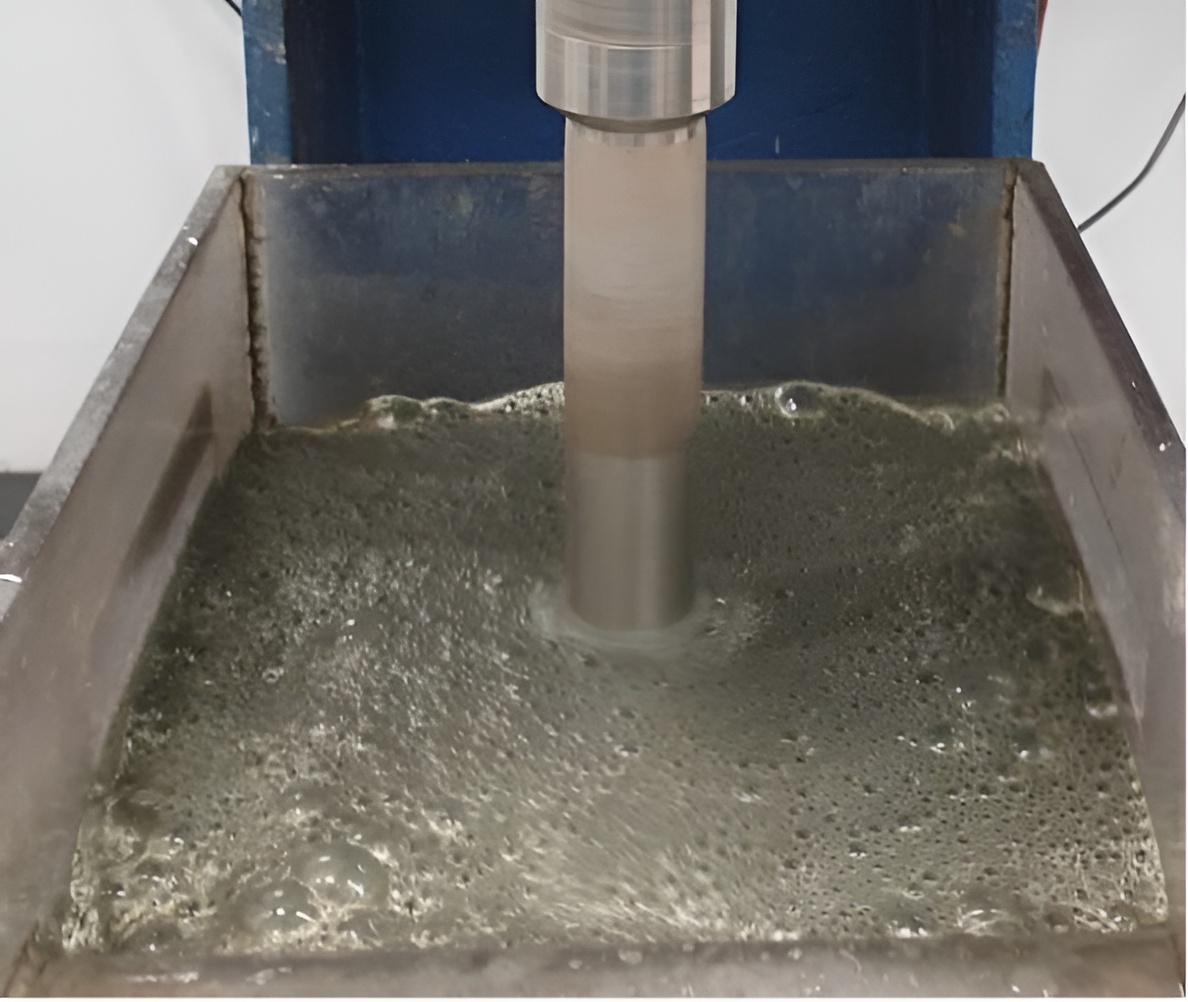

- Jord International on testing the NovaCell™, a coarse particle flotation technology that reduces energy and water use;

- And the use of Geopyora rock breakage testing to support mine-to-mill optimisation and geometallurgy.

“We also recently implemented the Hindsite platform to automate testing and training workflows. It’s about making the testing process more efficient, more consistent, and more scalable.”

Pilot Testing Without the Price Tag

Pilot-scale testing remains a cornerstone of serious feasibility studies—but Rob is quick to point out that “bankable” no longer means big.

“Historically, pilot plants required massive sample sizes and large, expensive equipment. That’s no longer the case,” he explains. “Improvements in process control now allow us to achieve bankable results from much smaller pilot plants. That saves time, cost, and material.”

The significance is especially pronounced in the critical minerals space. “These projects often rely on novel processing routes, and you can’t get funding unless you’ve demonstrated it works. That means pilot-scale data, but also product samples—particularly for applications like batteries, where the customer needs to test how the material behaves.”

A Pragmatic Approach to ESG

When asked about ESG and sustainability, Rob offers concrete examples rather than platitudes. “The Toowong Process™ stabilises arsenic at the mine site, so you don’t need to ship hazardous concentrate overseas. That reduces environmental risk and transport costs.”

Energy and water savings are also on the radar. “With the NovaCell™, you can coarsen the tailings stream and reduce water use, while shrinking the comminution circuit to save energy. These are real benefits, not just marketing points.”

What’s Next: Vanadium, Partnerships, and Scale-Up Services

Looking ahead, Rob is most excited about Core’s joint venture with South Africa’s X-Group to bring ion-exchange vanadium recovery to new markets.

“The IX technology has been proven in South Africa, but with Core’s help, we’re bringing it to Australia and beyond. It’s designed to extract vanadium from secondary sources like tailings, which is a huge opportunity,” he says.

Core is also expanding its laboratory partnerships and testwork services in collaboration with equipment and technology developers. “More announcements will be coming soon,” Rob adds.

Final Word

For juniors, mid-tiers, and even majors navigating the critical minerals rush, Rob’s message is clear: metallurgy matters—and it matters early.

“We help clients answer the hard questions upfront. Can it be built? Will it operate? Is it fundable?” he says. “Because at the end of the day, it’s not just about lab results. It’s about making the project real.”

Reprinted courtesy of The Rock Wrangler

Core Resources provides integrated metallurgical testing, process engineering and pilot plant services to support critical minerals projects from early-stage evaluation through to feasibility and commercialisation. Contact our team to learn more.