Leaching gold with a cyanide solution remains the most widely used hydrometallurgical process for the extraction of gold from ores and concentrates. Despite the difficulties and hazards of working with cyanide, no other process has yet been proven to be an economic viable alternative.

A paper published by L. Elsner in 1846 first correctly identified the chemical reaction that forms the basis of all gold cyanide leaching processes:

4 Au + 8 NaCN + O2 + 2 H2O → 4 Na[Au(CN)2] + 4 NaOH

The equation is well known, but the successful application of this reaction in a gold mining operation is rarely straightforward.

In a typical application, a slurry of the ground ore is mixed with cyanide in the presence of activated carbon. The carbon has a very high affinity for the aurocyanide complex and adsorbs the gold out of solution resulting in very high loadings on the carbon (typically 1000-4000 g/t). At the end of the leach the loaded carbon is removed from the slurry and the adsorbed gold is stripped out at high temperature and pressure with sodium hydroxide and cyanide solutions to form a high value electrolyte solution. Gold bullion is then recovered from the electrolyte by electrowinning.

That much is straight forward. However, there are a large number of critical factors which together determine the success (or otherwise!) of gold leaching in a mineral processing plant. Here is a summary of some of the key variables usually considered in the design of these cyanide leaching processes:

Gold Units: Is there enough gold present in the ore to pay for the costs associated with recovering it? Depending on all the other variables and costs associated, some projects can be viable with a gold grade as low as 0.5 g Au per tonne of ore, with sufficient tonnages. With lower gold grades beneficiation (usually flotation) is often used ahead of leaching to increase the grade of Au and reduce the quantity of ore to be leached.

Nature of Gold: The surface of a gold particle will typically be dissolved at a rate of around 0.2-0.5 µm of surface depth per hour in a cyanide leach. For large gold particles and nuggets, this is too slow to be fully dissolved in a typical processing plant. Much simpler and less expensive gravity methods are available to recover this gold. Cyanidation is used for gold that is distributed finely through a mineral matrix.

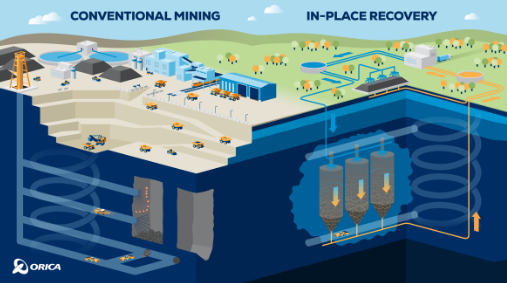

Liberation: Cyanide leaching will only be effective if the cyanide can come in contact with the gold particle. For this to happen, the ore should either be sufficiently porous for cyanide to reach the gold, or more usually the ore is crushed and ground to a size at which the surface of the gold is exposed – i.e. the gold is liberated.

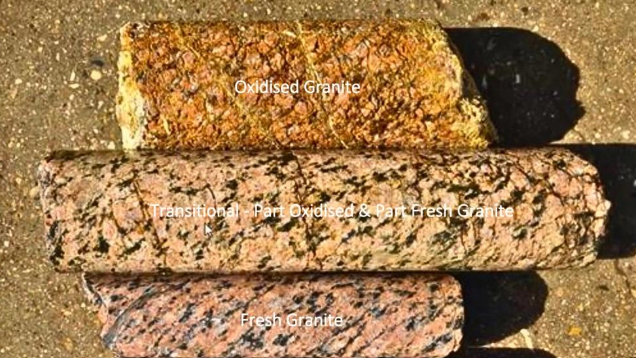

Mineralogy: A correct understanding of the mineralogical characteristics of the ore is the key element to successful extraction of gold from its host rock. Mineralogical factors that can substantially alter the performance of cyanide leaching are complex and can include:

Sulphide Minerals: Some sulphide minerals (e.g. pyrrhotite) will oxidise during the leach and generate acid. This reaction will consume the oxygen in solution, and without this oxygen the reaction of Au and Cyanide cannot proceed, regardless of the liberation of the gold. Artificial aeration or oxygenation will be required to meet the oxygen demands of the process. In addition to the retarding effects on the leaching process, the generated acid must also be continuously neutralised to prevent the formation of Hydrogen Cyanide (HCN) gas – increasing operating costs for the process. Lime is typically added to control and maintain the slurry pH to both assist reaction kinetics and suppress HCN formation.

Refractory Ores/Solid-Solution Gold: In some ores, Au can be locked inside the sulphide mineral matrix of the ore (so called solid solution), and the cost for the energy required to grind and liberate is simply too high to be viable. These are “refractory ores” and require a chemical, not simply physical, process to liberate gold from the surrounding rock. The Albion Process™, developed at Core’s laboratories in the 1990’s, is one such process and is now in use globally (see a recent report on a gold Albion Process plant here). Other processes for treating refractory ores include Pressure Oxidation (POx) and Bacterial Leaching (BIOX®).

Preg-robbing: Any microscopic carbon material in the ore will compete with the activated carbon to adsorb Au out of the cyanide solution, and prevent recovery (so called preg-robbing). Several other clay type minerals will have the same effect. Where preg-robbing material is present in the ore the process typically higher activated carbon inventories are used with more frequent stripping and regeneration cycles. Preg-robbing material can be deactivated prior to leaching by the addition of kerosene or diesel or similar blinding agents.

Cyanicides: Cyanide is an aggressive compound, and will react and be consumed by a number of mineral species other than gold – species known as cyanicides. These reactions must be carefully managed and where possible suppressed to prevent excess cyanide consumption causing the process to become uneconomic.

Leach Kinetics: The pH and the temperature of the reaction can affect the kinetics of the gold dissolution reaction. However the pH and temperature will also affect the kinetics of other deleterious reactions (like those outlined above), and determining the correct conditions for the leach can substantially affect the overall performance.

Environment and Safety: Cyanide use in most countries is strictly controlled, to reduce the risk of significant environmental damage or death through misuse or mishandling. In addition to inventory and handling restrictions at mining operations, process chemistry is often controlled using Calcium Hydroxide (Lime) to maintain optimum pH and suppress the formation of toxic Hydrogen Cyanide gas. Waste cyanide solutions are sometimes treated to regenerate cyanide for re-use (SART), or to break down the cyanide into harmless components (See our case study here on a recent cyanide detox project at Core.) Cyanide should never be used except at an authorised operation that complies with all applicable regulations.

The chemistry of cyanidation is well understood, but successfully applying it to a mineral resource requires a careful consideration of all these factors.

Core has extensive experience in the testing and optimisation of all aspects of gold leaching processes. Our metallurgists and process engineers are able to work with you to design and manage testwork programmes to achieve the goals required by your project. We are specialists in the treatment of refractory and difficult ores, and are proud of getting the ‘hard to find’ solution. Contact us today to discuss how we can work with you to get your project moving.